warping was easy because the yarns were thick. problems began later as i had to adjust the loom cords and all went beserk, shed opening was extremely small, lifting knife misbehaved, all sorts of things happened.the bad news is that it took me over 20 years to find out what works, the good news is that i finally found what works. when things are mechanically simple, there are few pieces, but the permutations grow exponentially.

and no one, not even the manufacturers, apparently know. tightening the cords, shortening them in conjunction to other pieces do nothing good.

it just took 2 drops of oil-who would guess oil on wood-to solve the various problems. it all came together.

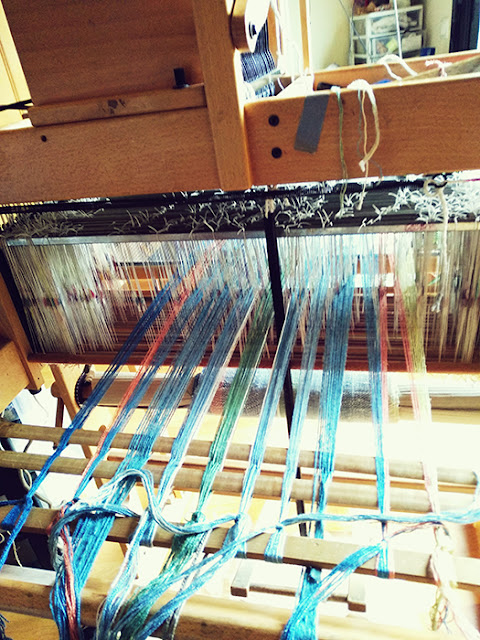

on with weaving. wanted to highlight the yarns as they were a beautiful nubby silk dyed in natural colors. there was madder, indigo in various shades, carrot tops and yellow from pomegranates.colors rotating in warp and weft.

the structure was plain weave but as the yarns were irregular it had ta certain saori look.had to use agar agar to strengthen the yarns against abrasion.

three meters off the loom before washing and ironing. there's a rustic charm to it.

neki desu